+86-13928815851

+86-13928815851

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

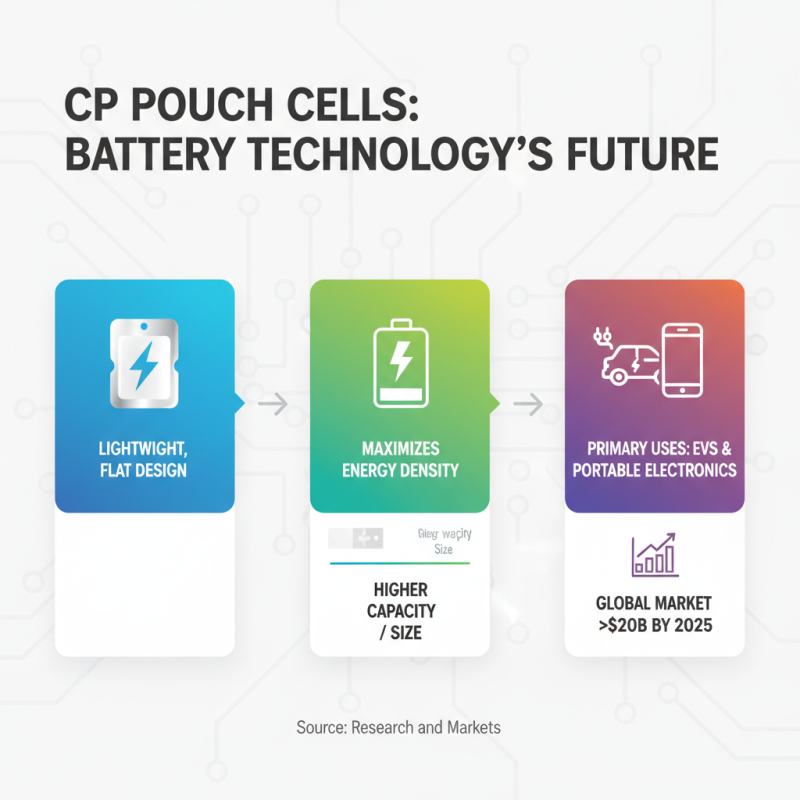

Cp Pouch Cells have emerged as a groundbreaking technology in the realm of energy storage, particularly within modern electronic devices and electric vehicles. These innovative battery cells are characterized by their unique pouch-like structure, which allows for a lightweight and flexible design, making them an ideal choice for applications where space and weight are crucial considerations. Unlike traditional cylindrical or prismatic cells, Cp Pouch Cells are capable of achieving higher energy densities, providing enhanced performance and efficiency in energy delivery.

In recent years, the demand for more compact and efficient power sources has grown exponentially, driven by advancements in technology and the increasing need for sustainable energy solutions. Cp Pouch Cells are at the forefront of this shift, offering a versatile solution that caters to a variety of uses, from portable electronics to electric transportation. Their design not only maximizes the energy-to-weight ratio but also facilitates faster charging times, thus aligning with the modern consumer's expectations for both convenience and performance. As we delve deeper into the mechanism and advantages of Cp Pouch Cells, it becomes evident that they play a pivotal role in shaping the future landscape of energy storage technology.

Cp pouch cells, also known as lithium polymer batteries, are a type of rechargeable battery that are characterized by their thin, flexible, and pouch-like structure. These cells have gained popularity in modern technology due to their lightweight design and high energy density compared to traditional cylindrical or prismatic lithium-ion batteries. Recent reports, such as those by the International Energy Agency, indicate that the demand for lithium polymer batteries is expected to grow by over 20% annually, driven largely by their applications in consumer electronics and electric vehicles.

The construction of Cp pouch cells typically involves a layer of lithium-ion electrolyte sandwiched between two electrodes, all enclosed in a flexible polymer casing. This design not only allows for a significant weight reduction but also facilitates a higher capacity for energy storage. Additionally, the pouch format enables more efficient packing within devices, maximizing the available internal space. According to a market analysis by Assessments and Industry Reports, the overall energy density of pouch cells has reached up to 300 Wh/kg, making them an attractive option for manufacturers seeking to enhance the performance of their products while reducing overall weight.

As the technology behind Cp pouch cells continues to evolve, advancements such as improved thermal stability and faster charging times are likely to emerge, further solidifying their position in sectors such as automotive and portable electronics. The growing emphasis on energy efficiency and sustainability is also propelling research into enhancing the lifecycle and reducing the environmental impact of these batteries, positioning Cp pouch cells as a critical component in the next generation of energy storage solutions.

Cp pouch cells, a significant advancement in energy storage technology, are notable for their unique design and structure which contribute to their efficiency and performance. Unlike traditional cylindrical or prismatic cells, Cp pouch cells utilize a flexible, lightweight polymer foil for their casing, allowing for a more compact and lightweight energy solution. This design facilitates greater energy density, typically reaching up to 250 Wh/kg, as reported in the 2021 Battery Technologies Market Analysis. The flat and flexible nature also provides versatility in applications, especially in modern electronic devices, electric vehicles, and renewable energy systems.

The inner structure of Cp pouch cells comprises multiple layers, including electrodes, separators, and an electrolyte, all stacked together in a manner that maximizes surface area for electrochemical reactions. This configuration not only enhances the cell’s capacity but also improves thermal management, reducing the risk of overheating. According to a recent report by Market Research Future, the pouch cells segment is expected to grow significantly, with a projected CAGR of 18% from 2022 to 2030, driven largely by their increasing adoption in high-performance applications.

With advancements in materials science, manufacturers are continually improving the structural integrity and safety of Cp pouch cells, making them a focal point for sustainable energy solutions in the tech-driven era.

Cp pouch cells represent a significant advancement in battery technology, notably utilized in electric vehicles (EVs) and portable electronics due to their unique design and efficient performance. Constructed with a lightweight, flat configuration, these cells maximize energy density, enabling manufacturers to produce batteries with a higher capacity relative to their size. A report by Research and Markets indicates that the global pouch battery market is expected to grow to over $20 billion by 2025, driven primarily by the increasing demand for energy storage solutions and electric mobility.

The working principles of Cp pouch cells revolve around their layered structure, where lithium-ion technology is predominantly used. These cells consist of a cathode, an anode, and electrolyte materials, all housed within a flexible pouch. During charging, lithium ions flow from the anode to the cathode through the electrolyte, while electrons travel through an external circuit, generating electrical energy. Upon discharging, the process reverses, allowing the stored energy to power devices. According to a study by IDTechEx, pouch cells exhibit an energy density ranging from 150 to 250 Wh/kg, making them a favorable choice for applications that require lightweight and compact power sources. As the technology continues to evolve, Cp pouch cells are being optimized for improved thermal stability and faster charging capabilities, further enhancing their application in modern technology.

Cp pouch cells, or lithium polymer pouch cells, are gaining traction in various modern technology applications due to their lightweight design and high energy density. These cells are primarily used in consumer electronics, electric vehicles, and portable power solutions. According to a report by Grand View Research, the global lithium polymer battery market is expected to reach approximately $25 billion by 2025, driven largely by the increasing demand for compact and efficient energy storage systems across diverse industries.

One of the most significant applications of Cp pouch cells is in electric vehicle (EV) technology. These cells offer a greater flexibility in design and configuration, enabling manufacturers to maximize the use of available space and reduce overall weight. A study from the International Energy Agency noted that EV sales surpassed 3 million units globally in 2020, highlighting the increasing reliance on efficient battery systems. Furthermore, companies are investing in advanced battery management systems that leverage the unique properties of Cp pouch cells to enhance performance and extend battery life, ensuring a sustainable future for the automotive industry.

In the realm of consumer electronics, Cp pouch cells are widely utilized in smartphones, laptops, and wearable devices. With device manufacturers focusing on thinner and lighter products, these batteries provide the ideal solution without compromising performance. Research from the Battery Innovation Center emphasizes that innovations in battery technology could lead to capacity improvements of up to 30% in the coming years, which would significantly impact product development in this sector. As technology continues to evolve, the role of Cp pouch cells will undoubtedly expand, offering new opportunities for efficiency and innovation.

Cp pouch cells are increasingly being used in various modern technologies, particularly in electric vehicles and portable electronic devices, due to their lightweight design and high energy density. One of the significant advantages of these cells is their ability to be produced in various shapes and sizes, allowing for flexible integration into devices with limited space. This versatility makes them ideal for applications that require optimizing the available space while maximizing power output. Additionally, the thinner form factor of pouch cells contributes to a reduction in weight, which is a critical factor in enhancing the overall efficiency and performance of devices.

However, the use of Cp pouch cells also presents several challenges. One of the primary concerns is thermal management, as these cells can be more susceptible to temperature variations compared to traditional cylindrical or prismatic cells. Effective cooling systems are essential to prevent overheating, which could lead to performance degradation or safety issues. Furthermore, the delicate nature of pouch cells can make them more vulnerable to physical damage, prompting the need for robust packaging solutions to safeguard the cells during usage. These challenges necessitate careful consideration during the design and manufacturing stages to ensure that the benefits of Cp pouch cells are fully realized while mitigating potential risks.

| Dimension | Details |

|---|---|

| Cell Type | Cp Pouch Cell |

| Form Factor | Flexible and Lightweight |

| Application Areas | Consumer Electronics, Electric Vehicles, Renewable Energy |

| Advantages | High Energy Density, Lightweight, Thinner Profiles |

| Challenges | Thermal Management, Mechanical Stability, Manufacturing Complexity |

| Lifespan | Generally Over 500 Charge Cycles |

| Efficiency | Typically 90% or Higher |