+86-13928815851

+86-13928815851

Leave Your Message

-

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER -

CONTACT NUMBER

CONTACT NUMBER

In today's fast-paced technological landscape, the demand for efficient and compact energy storage solutions is at an all-time high, making Cp Pouch Cells a focal point for innovation. According to a report by MarketsandMarkets, the global pouch cell market is projected to grow from USD 2.1 billion in 2020 to USD 5.9 billion by 2025, reflecting a compound annual growth rate (CAGR) of 22.2%. This surge is primarily driven by the increasing adoption of electric vehicles (EVs) and portable electronic devices, where space and weight optimization is crucial. Cp Pouch Cells, known for their lightweight design and high energy density, are becoming increasingly popular across various industries. By efficiently maximizing the performance and lifecycle of these cells, manufacturers can not only enhance the functionality of their products but also contribute to the sustainability goals within the energy sector. As we explore best practices in leveraging Cp Pouch Cells for modern applications, it is essential to understand the unique benefits they offer in today’s competitive market.

Cp pouch cells are becoming increasingly significant in contemporary applications due to their unique design features and inherent advantages. Notably, their lightweight and flexible structure allows for optimized space utilization, making them ideal for compact devices such as smartphones and wearables. According to a report from Markets and Markets, the global pouch battery market is projected to reach USD 23.33 billion by 2025, showcasing a compound annual growth rate (CAGR) of 14.07% from 2020. This rapid growth highlights the pressing need for efficiency in energy storage solutions, where Cp pouch cells excel due to their higher energy densities compared to traditional cylindrical or prismatic cells.

Furthermore, Cp pouch cells offer notable thermal management benefits, which are crucial in high-performance applications like electric vehicles (EVs) and renewable energy storage systems. Research from the International Energy Agency (IEA) indicates that the efficiency of battery systems in EVs is critical for adopting sustainable transportation methods. With advancements in thermal management technologies, Cp pouch cells can maintain optimal performance, thereby contributing to increased overall system efficiency. Additionally, their flat design facilitates easier integration into various products, making them a preferred choice for manufacturers looking to improve energy performance without compromising design.

In the quest to maximize efficiency in modern applications, the choice of configuration for Cp pouch cells is crucial. According to a report by Allied Market Research, the global pouch battery market is expected to reach $37 billion by 2027, driven primarily by the demand for lightweight and flexible energy solutions in consumer electronics and electric vehicles. Optimizing the design of Cp pouch cells involves selecting appropriate materials and dimensions to enhance energy density while maintaining safety standards. For example, adopting a higher packing density can significantly improve energy output per unit volume, which is vital for compact applications.

The configuration of Cp pouch cells also influences thermal management and charging cycles. A study by ResearchGate indicates that tailored thermal designs can increase the lifespan of these cells by up to 30%, making them a more sustainable choice for long-term use. By leveraging advanced thermal interface materials and optimizing cell layout, manufacturers can enhance the cooling efficiency, thereby ensuring stable performance under varying operating conditions. These strategic design choices play a pivotal role in meeting the evolving demands of modern technology while ensuring optimum safety and performance of Cp pouch cells.

This chart illustrates the performance metrics of Cp Pouch Cells, highlighting key factors affecting their efficiency in modern applications. As shown, these cells exhibit a high energy density, impressive cycle life, reasonable charge time, and a wide operational temperature range, making them suitable for various applications.

Maximizing efficiency in energy storage applications with Cp pouch cells hinges on adopting innovative strategies that enhance their performance. Recent advancements in lead-free ceramics and carbon-based materials present promising directions. The development of lead-free ceramics focuses on outstanding energy storage performance, which is vital for sustainable applications. By exploring the synthesis and characterization of these materials, we can optimize their integration in various energy systems.

Tips: When working with new material compositions, consider the following strategies: first, leverage the tunable properties of perovskite oxides, which offer enhanced ionic-electronic conductivity for better charge storage. Second, explore innovative approaches in nanotechnology to improve the functionality of your energy storage systems by incorporating functional nanomaterials. Finally, focus on collaborative optimization techniques such as aligning polarization and grain structures to unlock superior energy storage capacities in multi-layer ceramic capacitors.

The incorporation of two-dimensional Mo-based materials has also garnered attention for rechargeable metal-ion batteries, which prioritizes safety and energy density. Keeping abreast of these technological advancements will not only facilitate higher performance but also ensure sustainable energy solutions in modern applications.

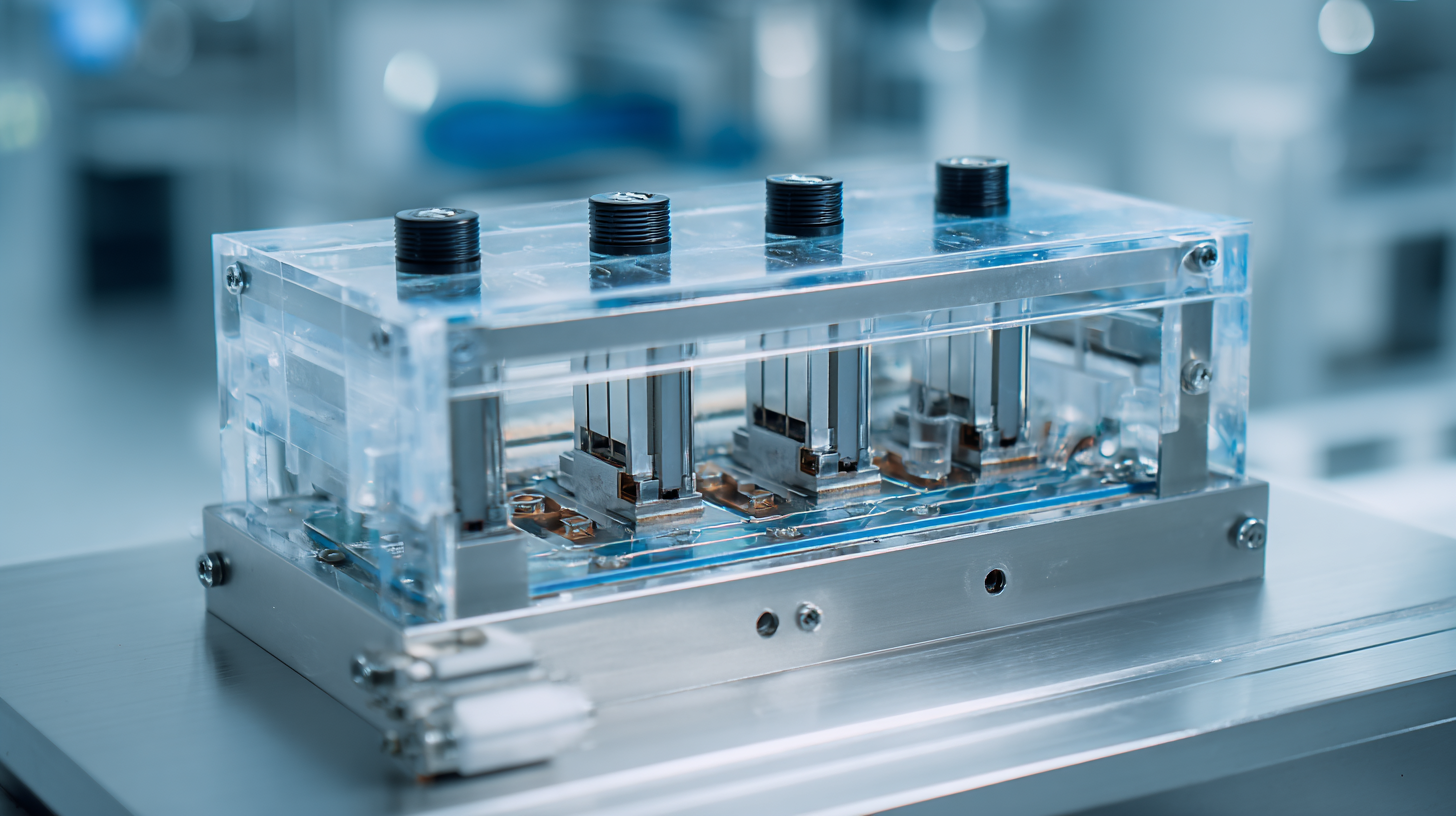

In recent years, advanced manufacturing techniques for Cp pouch cells have significantly transformed the landscape of energy storage solutions. According to a report by the International Energy Agency (IEA), the demand for efficient and lightweight battery solutions has surged, driven by the electric vehicle (EV) market. As of 2023, the global battery market is projected to reach $100 billion, with pouch cells expected to capture a notable share due to their superior energy density and design flexibility.

Implementing cutting-edge manufacturing processes, such as laser processing and automated assembly lines, can further enhance the production efficiency of Cp pouch cells. A study by TechInsights indicated that these techniques could reduce production costs by up to 20% while also improving the quality and uniformity of the cells. Furthermore, innovations in materials, like the use of high-capacity cathodes and novel electrolytes, are enabling higher performance and longer cycle life, establishing Cp pouch cells as a viable choice in modern applications ranging from consumer electronics to larger-scale renewable energy storage systems.

| Parameter | Value | Unit | Comments |

|---|---|---|---|

| Nominal Voltage | 3.7 | V | Typical for Li-Ion |

| Capacity | 3000 | mAh | High capacity for larger devices |

| Cycle Life | 500 | Cycles | Sustainable performance |

| Energy Density | 150 | Wh/kg | Higher density means smaller size |

| Manufacturing Speed | 50 | Units/hour | Improved throughput |

| Cost per Unit | $1.50 | USD | Economically viable option |

To ensure the longevity and performance of CP pouch cells in modern applications, implementing best maintenance practices is crucial. According to a report by the International Energy Agency (IEA), the efficiency of lithium-ion batteries, including CP pouch cells, can deteriorate significantly if not maintained properly. Routine checks on voltage levels and temperature can prevent overheating and cell swelling, which are common issues that can shorten their lifespan by up to 30%.

Moreover, it’s essential to operate CP pouch cells within their recommended charge and discharge cycles. A study published in the Journal of Power Sources indicated that consistently cycling these cells between 20% and 80% state of charge (SoC) can enhance their lifespan by as much as 50%. Implementing smart management systems that monitor and regulate these parameters can further optimize performance and energy output. By adopting these best practices, stakeholders can ensure that CP pouch cells continue to deliver high efficiency and reliability in various modern applications, from electric vehicles to renewable energy storage systems.